AFT Blog

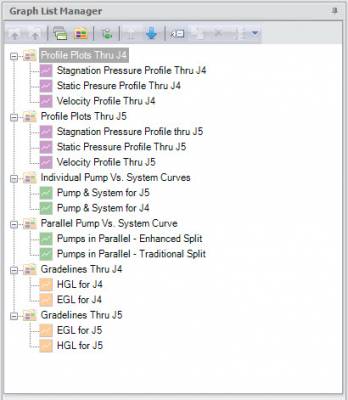

AFT software products have had powerful graphing capabilities for a very long time. Many types of graphs can be created with AFT products such as pump vs. system curves, profile plots along a flow path, gradelines and elevation profiles, transient plots (with AFT Impulse or the AFT Fathom XTS module), slurry system curves (with AFT Fathom SSL or AFT Impulse SSL modules), and selected solutions that allow you to plot various output parameters for desired pipes. All of these graphing capabilities are incredibly important to engineers as they analyze the hydraulic behavior of their system. The ability to customize the graphs...

When I started AFT back in 1994 I had the idea to develop a product for compressible flow in pipe systems. After AFT Fathom 1.0 was released in April 1994 I began research on numerical methods for compressible flow in pipe networks. Books and papers that claimed to offer methods for compressible flow inevitably focused on single pipe applications with adiabatic or isothermal flow - and often with ideal gases. I wanted to develop a real gas software that could model heat transfer and simulate pipe networks.

Calculating Flow Through an Orifice Using ASME MFC-3M-1989 and Irrecoverable Pressure Drop Equations

Recently, a customer calculated the mass flow rate of a fluid through an orifice using both the ASME standard MFC-3M-1989 and AFT Arrow. He was puzzled when this mass flow rate calculation differed by approximately 100 lbm/hr between the two methods, so he reached out to AFT for help in determining the reason for the discrepancy. The answer for the difference in flow rates on a basic level is that these two calculations are, fundamentally, not the same thing; ASME correlates differential pressure at pressure taps for purposes of flow measurement, while AFT Fathom and Arrow calculate the irrecoverable pressure drop...

Mismatched fluid handling machinery and the systems they service are a frequent occurrence in industrial, municipal and commercial fluid transfer installations. And, as I found out this morning, in residential installations. Specifically, in the residential installation in which I personally live.

Well, if the answer is "more than one", then you are probably struggling to deal with way more model files than you need to be. With all AFT products, the Scenario Manager is an incredibly powerful feature that allows one to model several different cases within a single model file. This includes different operating conditions, multiple pump configurations, different piping, system expansions, hot days, cold days, insulation, fouling and pipe scaling, etc. The list of different cases that can be modeled is essentially endless! So, I have said it once, and I will say it again...The Scenario Manager is one of...

When dealing with a compressible gas system, heat transfer and thermal effects are very important to account for. When a gas is flowing down a pipeline, it will cool down as the gas expands due to the frictional pressure drop. Many would say that adiabatic or isothermal conditions will bracket the potential flow rates that are possible for a constant pressure drop in a pipe. However, this is not the case. If a gas is cooled or heated as it flows down the pipeline, the flow rates that can result for a given pressure drop can actually be outside the “bounds”...

It is possible to model the shell side and tube side of a heat exchanger in AFT Fathom and AFT Arrow where the “hot fluid and cold fluid” circuits can also be included for both sides of a heat exchanger in a single model file! This can be accomplished by creating a "thermal link" between two heat exchangers and using the “Heat Transfer with Energy Balance (Multiple Fluids)” option in the System Properties window.

As shown in Figure 1 below, there are two separate systems modeled on the same Workspace. The left side of the system is an auxiliary cooling water loop while the right side system is the hot oil circulation loop. The two heat exchanger junctions that are highlighted in the red box, J8 and J18, represent the tube side and shell side of a single heat exchanger. The cooling water circuit is on the tube side of the heat exchanger and the hot oil loop is on the shell side of the same heat exchanger. These heat exchanger junctions are “thermally linked” together, as they represent the same physical heat exchanger. Therefore, their resulting heat rates will be the same, but opposite in sign.

An important requirement to keep in mind that will allow the modeling of two sides of a heat exchanger with the “thermal linking” feature is that both fluids on each side of the heat exchanger must remain in fully liquid phase for AFT Fathom (or fully gas phase for AFT Arrow). Therefore, there cannot be any phase change in either fluid circuit or through the heat exchanger itself.

First step is to build a model of the system and include both cooling water and hot oil loops. After all the pipes and junctions are laid out on the Workspace (but not defined), open up the System Properties window and choose the "Heat Transfer with Energy Balance (Multiple Fluids)" option as displayed in Figure 2. A single “default” fluid must be selected and defined. The individual fluids used in each loop will be defined soon.

Next, the pipes and junctions can be defined with their various thermal models and characteristics (except for the two heat exchanger junctions that will need to be modeled as two sides of one heat exchanger. This will be specified later).

In order to use the "Multiple Fluids" option in System Properties so that two sides of a heat exchanger can be thermally linked, "Fluid Groups" must be created. Before fluids can be assigned to specific “Fluid Groups”, separate groups of all the pipes and junctions in each individual circuit need to be created first.

As shown in Figure 3, select all the pipes and junctions that make up one of the circuits, such as the cooling water loop. Then from the Edit menu, click "Groups", then "Create", and give that group of pipes and junctions that are selected, a name.

Then, select the pipes and junctions that make up the hot oil side. With those objects selected, click "Edit", then "Groups", then "Create" and give the hot oil loop a name.

After two separate groups for each loop have been created, the specific fluids that will be used for each group can now be defined. Click "Edit", then "Groups", then "Fluids". Check both boxes so that both fluid groups can be used.

For the cooling water circuit, click the box with the little dots in the "Fluid" column, then specify the fluid properties, like that in Figure 4. Any of the fluid options are available, except for "User Specified Fluid" (because the "User Specified Fluid" option does not model heat transfer).

Then, specify the fluid properties for the hot oil loop by clicking on its box with the little dots.

After a particular fluid has been chosen for each fluid group, click OK.

Now, the two heat exchangers can be "thermally linked" together.

Open one heat exchanger, and on the Thermal Data tab, specify one of the Effectiveness-NTU thermal models, then check the box to "Link to Heat Exchanger", and select the other heat exchanger from the drop-down menu that you want to link to. Then specify the required parameters. Figure 6 illustrates how to thermally link the cooling water loop tube side with a “Counter-Flow” thermal model and it will link to the Hot Oil Loop heat exchanger.